As global demand for singing bowls continues to rise across spiritual, therapeutic, and wellness markets, importers and distributors are placing greater emphasis on product certification, quality standards, and regulatory compliance. For manufacturers and exporters, ensuring that singing bowls meet these international requirements is no longer optionalit's essential for business growth and reputation.

At Singing Bowl Specialist, we prioritize quality assurance at every level—from raw material sourcing to acoustic tuning and packaging. This article outlines the key certifications, compliance protocols, and quality benchmarks that our brand follows to meet and exceed global expectations.

Why Quality and Certification Matter in Singing Bowl Exports

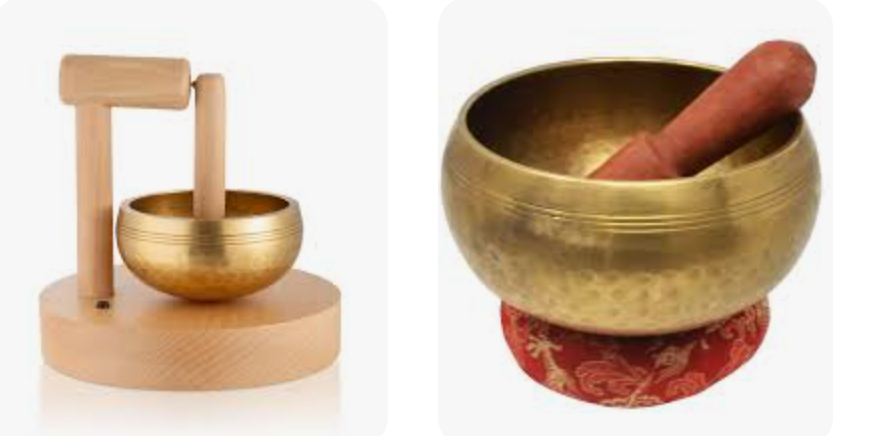

Singing bowls are not just decorative items—they are functional instruments used in sound therapy, meditation, yoga, and clinical settings. As such, their construction, material integrity, tonal accuracy, and safe usage must be verifiable and traceable.

Importers in countries such as the United States, Germany, Japan, Australia, and the U.K. often require certifications for :

- Material safety and composition

- Workplace ethics and fair trade

- Tonal consistency and acoustic quality

- Compliance with customs and import regulations

This is where Singing Bowl Specialist stands out—by offering fully documented and certified singing bowls ready for international markets.

Key Certifications for Singing Bowl Exports

1. Certificate of Origin (COO)

This document verifies that the singing bowls are manufactured in India, which is important for trade agreements, import tax benefits, and legal trade compliance. Every export consignment from Singing Bowl Specialist includes a COO issued by the relevant chamber of commerce.

2. Material Composition Certificate

Quality-conscious buyers expect transparency about what their products are made from. At Singing Bowl Specialist, our singing bowls are tested and certified for metal purity. Most bowls are crafted from:

- Seven-metal alloy (including gold, silver, copper, zinc, iron, tin, and lead)

- Brass or bronze-based alloys for machine-made bowls

Each batch is accompanied by a Material Safety Data Sheet (MSDS) confirming non-toxic and safe composition.

3. Acoustic Frequency Certificate

This unique certification ensures the sound resonance and frequency of the bowl meet therapeutic or chakra alignment purposes.

At Singing Bowl Specialist, we use digital frequency tuners and resonance testing to verify:

- Accurate tuning (e.g., C, D, E, F, G, A, B for chakra bowls)

- Harmonic sound layers

- Sustain length and clarity

We provide frequency test reports upon request for healing practitioners and yoga studios needing precise sound alignment.

4. RoHS Compliance (Restriction of Hazardous Substances)

Many countries, particularly in Europe, require RoHS certification, which restricts the use of harmful substances like lead, mercury, cadmium, and hexavalent chromium in products.

5. Fair Trade and Ethical Sourcing Certification

Consumers worldwide are increasingly choosing products that support ethical labor and sustainability. Our brand partners with Fair Trade-approved artisan clusters, where we ensure:

- Fair wages and safe working conditions

- No child labor

- Support for artisan communities and women-led cooperatives

6. ISO 9001: Quality Management System (QMS)

Though not mandatory, ISO 9001 certification enhances business credibility by verifying adherence to a robust quality control process. Singing Bowl Specialist follows ISO 9001 aligned internal protocols, including:

- Multi-step product inspections

- Acoustic and durability testing

- Batch-wise quality sampling

- Customer feedback integration for continuous improvement

Singing Bowl Specialist’s In-House Quality Standards

Beyond documentation, Singing Bowl Specialist implements an 8 stage quality control process, including :

- Raw Material Inspection – Testing for purity and defects.

- Artisan Checkpoint – Monitoring hammering symmetry and wall thickness.

- Tuning Assessment – Evaluating resonance and frequency alignment.

- Visual Aesthetics Review – Ensuring polish, etching, and uniform finish.

- Anti-Tarnish Treatment – Applying protective wax/oil to avoid oxidation.

- Final QC Audit – Pre-shipment cross-verification of specs.

- Packaging Test – Ensuring shock-absorbent, export-grade packing.

- Documentation & Labelling – Attaching all required certificates and export labels.

Regulatory Documents for Smooth Customs Clearance

Every order exported by Singing Bowl Specialist includes a full set of required documents, such as:

- Commercial Invoice

- Packing List

- Bill of Lading / Airway Bill

- HS Code declaration

- Export declaration (EX1 form for EU orders)

Tailored Compliance for Global Buyers

We understand that different countries require unique standards. That’s why Singing Bowl Specialist offers:

- Country-specific documentation

- Custom declarations and labels

- Certificates for health & wellness usage

- Private lab testing (on request)

Quality Is the Passport to Global Markets

As competition intensifies in the global singing bowl export market, what sets a brand apart is verifiable quality and trustworthy certification. At Singing Bowl Specialist, we believe that every bowl exported is a reflection of India’s heritage, our artisan community, and our professional commitment.

Frequently Asked Questions (FAQ)

Q1. Are certifications required to export singing bowls internationally?

Certifications are not always legally required but are highly recommended. They enhance product credibility, meet buyer expectations, and are often necessary to enter regulated markets like the EU, USA, or Australia.

Q2. What are the most important certifications for singing bowl exports?

Key certifications include:

- ISO 9001: For quality management systems

- CE Marking (Europe): For safety compliance, especially for crystal bowls

- RoHS Compliance: For restriction of hazardous substances

- REACH Compliance (EU): For chemical safety in metals

- Fair Trade Certification: For ethically produced goods

- SGS/Intertek Testing Reports: For quality and material verification

Q3. What quality standards do international buyers look for?

Buyers expect:

- Consistent tone and resonance

- Smooth finish and detailed craftsmanship

- Use of non-toxic, lead-free materials

- Sustainable and ethical production methods

- Durable, export-grade packaging

Q4. Are there specific standards for crystal singing bowls?

Yes. Crystal bowls must often comply with:

- CE certification (for electronic or amplified versions)

- Material purity tests (usually ≥ 99.9% quartz)

- Packaging standards to prevent breakage during shipping

Q5. How can exporters ensure product quality before shipment?

They should:

- Perform sound testing for pitch accuracy

- Inspect for cracks, dents, or finishing flaws

- Use third-party labs (like SGS or TÜV SÜD) for metal composition analysis

- Ensure proper labeling and packaging for global transit